Move-E-Star in Action (4:50 minutes)

Move-E-Star – Payload 5 to 120 tons

HIGH PAYLOAD/WEIGHT RATIO

OMNIDIRECTIONAL MOBILITY

-

Free maneuverability

-

Maximum placement precision

The move-e-star moves effortlessly in any direction. It is rotatable around each vertical axis, also those located outside the move-e-star. This omnidirectional mobility, also known as translational and rotational maneuverability, is otherwise only achieved by air cushion means of transport. But unlike those, the move-e-star can handle the rough floors encountered in production facilities and situations.

Our customers appreciate the excellent steering precision and positioning accuracy when it comes to omnidirectional mobility and maneuverability.

This frees up valuable space in expensive production areas for applications other than for transportation.

PRECISION

Loads must be taken up and set down with high accuracy and steadiness, and so also the positioning at or on handling machines, to ensure the rapid flow of the process without the need for readjustments.

The means of production should also be set down exactly at the machining station when transported from one point of use to the next. This also eliminates costly set-up times.

Move-E-Star in Action – Precision (1 minute)

This is where the omnidirectional mobility and maneuverability of the move-e-star proves itself by setting down the transported load with pinpoint accuracy.

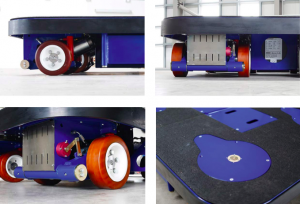

RUNNING GEAR

-

Low surface pressure due to large wheels and large number of wheels

-

Dynamic leveling

(handles thresholds and gradients while keeping transport surface horizontal)

-

Unaffected by dirt

-

Unaffected by external objects

-

Adaptable to different (solid) floor conditions

-

Modular design

Take a break and check this out…

INDEPENDENT WHEEL SUSPENSION

- Unaffected by uneven floor conditions

- Even load distribution on uneven floors

STEERING

- Energy-efficient steering due to roll-steering (no steering motors)

- Low floor shear load through roll steering

TRANSPORT PLATFORM

-

Customized design meets customer needs

LINKING – see Modularity below

-

Two or more vehicles may be connected mechanically or electronically.

-

Afterwards it is possible to control them as a single unit.

MODULAR DESIGN – MODULARITY

To transport heavy loads in tight spaces and aisles, special challenges need to be overcome. This is where our modular axle design provides the basis for multiple structural design option allowing the wheel size and the number of axles of the move-s-star to be tailored to the application and load-bearing capacity.

TECHNICAL FUNCTIONALITY

The move-e-star is distinguished by its low overall height and excellent maneuverability. The drive axles, in which the traction drive, the steering and lifting system are integrated, are the core of the unit.

The move-e-star is a platform that provides mobility to a variety of structures.

In its basic application the move-e-star transports goods, production parts, production equipment and similar objects on its loading platform.

The load-handling capabilities of the unit can be highly customised. One customer had the need to transport goods of different surface finishes. To meet this need, HIT has designed the load-handling capacity of the move-e-star to be interchangeable at the touch of a button and without additional assembly work for two surface finishes.

Other lifting devices can also be readily installed on the move-e-star. For example, HIT has delivered two move-e-stars, each of which has four folding and telescopic lifting columns to handle large scaffold structures.

The transport platform can be equipped to meet the specific requirements of the operator. See above and below…

TRACTION AND STEERING DRIVE

The move-e-star can be operated in lengthwise and transverse travel as well as in an independent omnidirectional mobility mode. These operating modes and the infinitely variable steering drives provide optimum maneuverability in tight spaces and aisles.

Take a break and check this out…

LIFTING SYSTEM

The integrated lifting system enables the move-e-star to independently pick up and set down the load. The automatic level control ensures smooth and safe transport on uneven surfaces.

Move-E-Star in Action – Lifting (1 minute)

The running gear of the move-e-star integrates a lifting system. The unit is moved in underneath the load, which is then picked up, transported and set down again. The move-e-star is then ready for the next task. The benefits to the customer are obvious. The low height of the move-e-star is an advantage, as a separate device for lifting the load is not necessary. In addition, the platform is less complex, there are fewer parts to maintain and replace in case such a need arises. The move-e-star is a single-unit transport platform, which is tailored to provide optimal functionality.

AUTOMATIC MODE

Industry 4.0: not only the produced goods, but also the means of production and machinery become mobile. The path the produced goods take can vary from one piece to another. The means of production are now being used at one point in the factory, but must then shortly after be available at another point. This can only be achieved when goods and means of production can find their own way to the respective positions where they are to be processed or used.

Move-E-Star in Action – Automatic (1 minute)